Sizing a 90°BSP FEMALE 60°CONE fitting requires four clear steps. First, identify the thread type and size. Next, confirm the 60° cone angle. Then, check the 90° orientation. Finally, use a sizing chart. Anyone can size these fittings by following these simple steps.

Key Takeaways

- Follow four simple steps to size the fitting: identify thread type and size, confirm the 60° cone angle, check the 90° bend orientation, and use a sizing chart to find the right fit.

- Use proper measuring tools like calipers, pitch gauges, and angle finders to get accurate measurements and prevent leaks or connection failures.

- Avoid common mistakes by verifying thread types, measuring the cone angle carefully, checking bend orientation, and always double-checking your measurements against trusted sizing charts.

90°BSP FEMALE 60°CONE Fitting Overview

Definition and Key Features

The 90°BSP FEMALE 60°CONE fitting serves as a critical component in hydraulic systems. This fitting features a female British Standard Pipe (BSP) thread and a 60-degree cone seat, which together create a secure, leak-free connection. Manufacturers use durable carbon steel or stainless steel to ensure the fitting withstands high pressure and resists corrosion. The 90-degree elbow design allows for flexible hose routing, making it easier to install in tight spaces.

Key features include:

- BSP thread compatibility for reliable connections.

- 60° cone sealing surface for optimal leak prevention.

- Swivel functionality for easy hose positioning.

- Robust construction for long service life.

- ISO 9001 certification, which confirms adherence to international quality standards.

- Customizable dimensions to fit specific hydraulic requirements.

- Reusable design that simplifies maintenance and reduces downtime.

Technical documentation from leading hydraulic fitting suppliers highlights the importance of correct thread type, sizing, and surface treatment. These factors ensure the fitting performs reliably in demanding environments such as automotive, transportation, and industrial applications.

Visual Identification Tips

Identifying a 90°BSP FEMALE 60°CONE fitting involves several visual checks.

Tip: Always inspect the fitting before installation to confirm compatibility and prevent leaks.

- Look for markings on the fitting, such as part numbers or size indicators, often found on the coupler or adapter.

- Examine the threads to determine if they are female BSP and check for a 60° cone seat inside the fitting.

- Use a digital caliper to measure the inner diameter of the female thread. This helps confirm the correct size.

- Compare the fitting’s shape and measurements with sizing charts or dimensional tables from trusted sources.

- Check for an O-ring or sealing component, which enhances leak prevention.

Visual reference guides and charts from hydraulic industry resources provide detailed images and descriptions. These tools help users match their fitting to the correct type and size, ensuring a proper fit in hydraulic assemblies.

90°BSP FEMALE 60°CONE Sizing Specifications

Thread Size (BSP) Explained

Thread size plays a crucial role in selecting the correct 90°BSP FEMALE 60°CONE fitting. BSP, or British Standard Pipe, uses a standardized thread profile that ensures compatibility with a wide range of hydraulic components. Each BSP thread size has a specific pitch and diameter. Technicians often refer to sizing charts to match the thread diameter and pitch with the correct fitting. Using the wrong thread size can lead to leaks or connection failures. Always check the thread markings on the fitting and compare them with industry charts for accuracy.

Understanding the 60° Cone Angle

The 60° cone angle forms the sealing surface inside the fitting. This angle creates a metal-to-metal seal that resists leaks, even under high pressure. JIS (Japanese Industrial Standards) hydraulic fittings specify the 60° cone angle for several reasons:

- The angle provides a robust, leak-resistant connection.

- It supports high-pressure hydraulic applications.

- JIS standards highlight the 60° cone as a critical feature for reliable sealing, especially under dynamic pressure.

- The 60° cone differs from other standards, such as JIC (37°) and SAE (45°), making it unique in performance.

This design ensures the 90°BSP FEMALE 60°CONE fitting performs well in demanding environments.

Measuring the Fitting: Tools and Points

Accurate measurement ensures the fitting matches system requirements. Technicians use several tools for this process:

- Dial bore gauges and telescoping gages measure internal diameters.

- Inside micrometers check roundness and internal size.

- Go No-Go gauges confirm if the fitting meets tolerance limits.

- Angle measuring tools, such as sine bars, verify the 60° cone angle.

For best results, measure at key points: the internal thread diameter, the cone seat angle, and the overall fitting length. Consistent measurement techniques and clear documentation help maintain accuracy and repeatability.

90°BSP FEMALE 60°CONE Step-by-Step Sizing Guide

Identify Thread Type and Size

Accurate sizing begins with identifying the thread type and size. Technicians first determine if the fitting has male or female threads. Male threads appear on the outside, while female threads are on the inside. Next, they distinguish between tapered and parallel threads. Tapered threads show a change in diameter along the length, while parallel threads maintain a consistent diameter. Using a caliper, they measure the crest-to-crest diameter at several points. This step helps confirm if the thread is straight or tapered. A pitch gauge then measures the distance between threads, ensuring the correct pitch. After gathering these measurements, technicians compare them to industry charts to confirm the thread standard, such as BSP. These steps help prevent mismatches and ensure the fitting will connect securely in hydraulic systems.

Tip: Always use a caliper and pitch gauge for precise measurements. Visual inspection alone may lead to errors.

Confirm the 60° Cone Angle

The next step involves confirming the 60° cone angle inside the fitting. This angle forms the sealing surface, which is critical for leak prevention. Technicians use angle measuring tools, such as sine bars or electronic wedges, to check the cone angle. Industry guidelines recommend measuring wedge profiles at a standard depth and comparing the results to reference data. Measurements should focus on the central area of the cone, and the results must agree with reference values within a small margin, typically 2%. This process ensures the cone angle matches the required specification and provides a reliable seal under pressure.

Check the 90° Bend Orientation

Checking the 90° bend orientation is essential for proper installation and long-term performance. The orientation of the bend affects how the fitting handles stress and vibration. Engineering studies show that the geometry of a 90° elbow, especially the ratio of its mean radius to wall thickness, influences where fatigue cracks may form. Accurate sizing and correct orientation help prevent premature failure and extend the life of the hydraulic system. Technicians should visually inspect the bend and confirm it matches the required direction for the hose assembly.

Note: Proper bend orientation not only ensures a good fit but also protects the system from unnecessary stress and potential leaks.

Use a Sizing Chart Example

After gathering all measurements, technicians consult a sizing chart. These charts list thread sizes, cone angles, and fitting dimensions. By matching their measurements to the chart, they can quickly identify the correct 90°BSP FEMALE 60°CONE fitting. Sizing charts simplify the selection process and reduce the risk of errors. Many manufacturers, including Zhejiang Huacheng Hydraulic Mechinery Co., Ltd., provide detailed charts for their products. Using these resources ensures the chosen fitting will integrate seamlessly with existing hydraulic components.

| Thread Size (BSP) | Thread Pitch (mm) | Cone Angle | Typical Application |

|---|---|---|---|

| 1/4″ | 19 | 60° | Light-duty hoses |

| 3/8″ | 19 | 60° | Medium-duty hoses |

| 1/2″ | 14 | 60° | Heavy-duty hoses |

Callout: Always double-check your measurements against the sizing chart before final selection.

90°BSP FEMALE 60°CONE Common Sizing Mistakes

Mixing Up Thread Types

Many users confuse BSP threads with other types, such as NPT or metric threads. This mistake often leads to poor connections and leaks. BSP threads have a unique profile and pitch. Technicians should always compare the thread with a reference chart before installation. Using the wrong thread type can damage both the fitting and the hydraulic system.

Tip: Always check for thread markings and use a pitch gauge to confirm the thread type.

Overlooking the Cone Angle

Some installers ignore the importance of the cone angle. The 60° cone creates the seal that prevents leaks. Technical analyses show that overlooking or misjudging the cone angle can cause major problems. In anchorage systems, inaccurate cone angles lead to errors in predicting crack paths and load capacity. Field tests reveal that even small differences in the cone angle can change how the fitting performs under pressure. Accurate measurement of the cone angle ensures the fitting works as designed and maintains system safety.

Ignoring the 90° Bend

The 90° bend in the fitting is not just for appearance. It directs the flow and affects how the hose routes through the system. If users ignore the bend orientation, they may create stress points or kinks in the hose. This can shorten the life of the assembly and increase the risk of leaks. Always check that the bend matches the required direction for the application.

Not Using Proper Measuring Tools

Accurate sizing depends on the right tools. Using the wrong tool or skipping calibration can lead to errors. Measurement protocols highlight the need for reliable instruments, proper storage, and regular maintenance. Technicians who use well-calibrated tools and follow best practices get consistent, safe results. These habits also help meet industry standards and prevent costly mistakes.

Note: Investing in quality measuring tools and maintaining them properly ensures long-term accuracy and safety.

90°BSP FEMALE 60°CONE Quick Reference Sizing Chart

A quick reference sizing chart helps users select the correct fitting for their hydraulic systems. Reliable charts use precise measurements and follow international standards. Manufacturers like Tianjin Henghua Pipeline Technology Co., Ltd. and Zaozhuang Tianyi Industry Co., Ltd. produce fittings that meet ISO 9001 certification. These companies use strict quality control and offer customizable options, which ensures the accuracy of their sizing information.

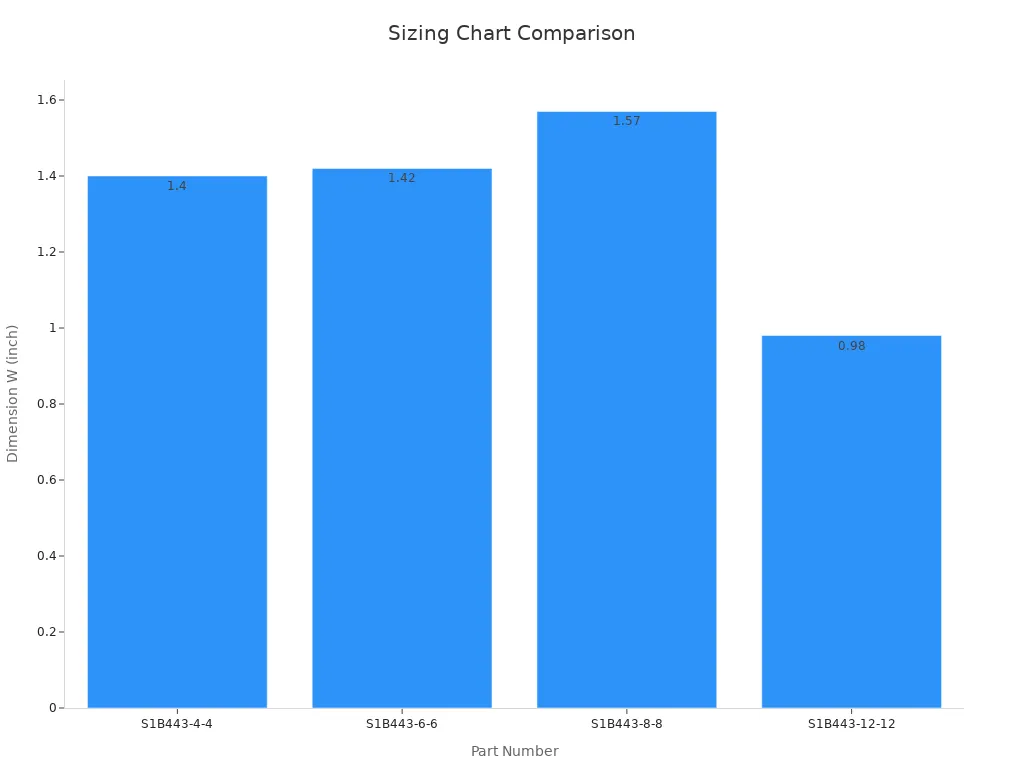

The table below lists common sizes for 90° BSP Female 60° Cone fittings. It includes thread size, hose inner diameter, and key dimensions in both inches and millimeters. Each part number matches a specific fitting, making selection easier for technicians and engineers.

| Part Number | Thread Size (inch) | Hose Inner Diameter (inch) | Dimension A (inch/mm) | Dimension E (inch/mm) | Dimension H (inch/mm) | Dimension W (inch) | Dimension B (inch/mm) |

|---|---|---|---|---|---|---|---|

| S1B443-4-4 | 1/4×19 | 1/4 | 2.4 / 61 | 1.14 / 29 | 17 / 19 | 1.4 | 36 |

| S1B443-6-6 | 3/8×19 | 3/8 | 2.76 / 70 | 1.02 / 26 | 19 / 22 | 1.42 | 36 |

| S1B443-8-8 | 1/2×14 | 1/2 | 3.19 / 81 | 1.02 / 26 | 22 / 27 | 1.57 | 40 |

| S1B443-12-12 | 3/4×14 | 3/4 | 3.3 / 84 | 1.3 / 33 | 23 / 32 | 0.98 | 25 |

Tip: Always verify the part number and dimensions before ordering to ensure a perfect fit.

Industry charts often compare key dimensions to help users visualize differences between fittings. The following bar chart shows how Dimension W varies across different sizes:

Suppliers with verified business licenses and third-party audits, such as Zaozhuang Tianyi Industry Co., Ltd., further support the trustworthiness of these sizing charts. Their commitment to quality and transparency gives users confidence when selecting fittings for demanding hydraulic applications.

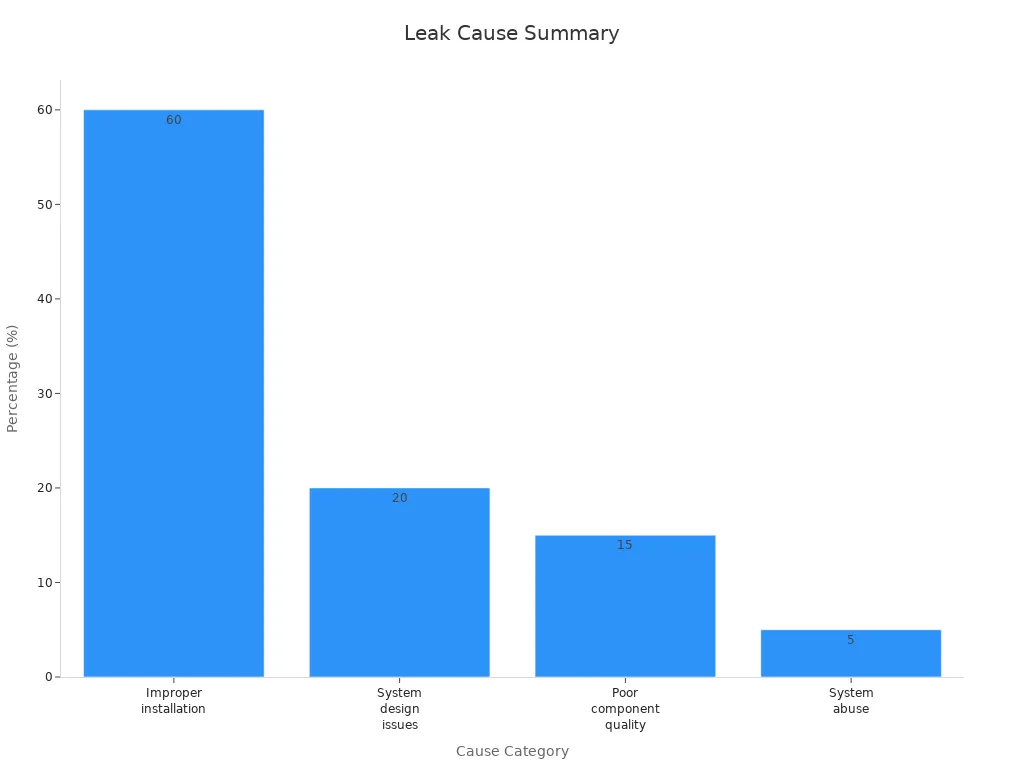

Selecting the right 90°BSP FEMALE 60°CONE fitting follows a clear process: identify thread type, confirm cone angle, check bend orientation, and match with a sizing chart. Proper sizing prevents leaks and supports safe hydraulic connections. The data below highlights why accuracy matters:

| Aspect | Evidence Summary |

|---|---|

| Leak Cause Distribution | Improper installation causes ~60% of leaks; system design issues cause ~20%; poor component quality ~15%; system abuse ~5%. |

| Routing | Proper routing avoids strain on joints, ensures accessibility, and allows expansion/contraction, preventing leaks. |

| Bending | Accurate measurement and bending with proper tools prevent misfit tubes that cause leaks. |

| Clamping | Adequate clamping reduces vibration and strain, preventing fittings from loosening and leaking. |

| Component Quality | High-quality fittings made to SAE standards reduce leaks; use of inferior or unknown fittings increases leak risk. |

| Assembly Techniques | Recommended methods like Flats from Wrench Resistance (FFRW) for flare fittings ensure proper sealing. |

| Cost Impact | Even small leaks cause significant fluid loss and cost over time, emphasizing the importance of leak prevention. |

| Preventive Measures | Training, proper tools, and maintenance manuals support leak-free assembly and system longevity. |

Technicians who follow these steps and use the provided chart can select fittings with confidence and maintain reliable, leak-free systems.

FAQ

What tools help measure a 90° BSP Female 60° Cone fitting?

Technicians use calipers, pitch gauges, and angle finders. These tools ensure accurate measurements for thread size and cone angle.

Can users install these fittings without special training?

Most users can install these fittings by following the sizing guide and using proper tools. Always check the manufacturer’s instructions for best results.

Are 90° BSP Female 60° Cone fittings compatible with all hydraulic hoses?

These fittings work with many hydraulic hoses. Always verify hose size and thread type before connecting. Compatibility ensures a leak-free and secure system.

Post time: Jun-27-2025