Selecting between Metric and NPT fittings shapes the efficiency and reliability of hydraulic systems worldwide. Engineers recognize that correct fitting choice prevents leaks, reduces energy consumption, and extends component life. Improper selection or misunderstanding npt thread specifications often results in system inefficiency, safety risks, and higher maintenance costs. Global projects demand fittings that match pressure ratings, temperature limits, and fluid compatibility. Regular maintenance and precise sizing further support system longevity and reduce operational disruptions.

Key Takeaways

- Metric fittings use millimeter threads and often seal with O-rings, while NPT fittings use inch-based tapered threads that seal by thread compression and need sealants like Teflon tape.

- Metric and NPT fittings cannot connect directly; adapters are necessary to join these different thread types safely and prevent leaks.

- Choosing the right fitting depends on system pressure, temperature, fluid type, and regional standards to ensure reliability and compliance.

- Proper installation and maintenance, including correct torque and seal inspection, prevent leaks and extend hydraulic system life.

- Understanding regional preferences and sourcing from trusted suppliers helps secure compatible fittings and adapters for global hydraulic projects.

Understanding Metric and NPT Fittings

What Are Metric Fittings?

Metric fittings serve as a cornerstone in hydraulic systems, especially across Europe and Asia. These fittings use threads measured in millimeters, with both the diameter and pitch specified (for example, M14x1.5). Engineers rely on tools like thread pitch gauges and calipers to ensure precise measurement and compatibility. Metric fittings often feature parallel threads and employ advanced sealing methods, such as O-rings or bonded seals, to prevent leaks and maintain system integrity. The following table summarizes key technical aspects:

| Specification Aspect | Details & Evidence |

|---|---|

| Metric Port Types | DIN (24° cone angle), ISO 6149 (threaded with O-ring seal), BSPP |

| Thread Specifications | Metric threads in millimeters, measured with pitch gauges and calipers |

| Sealing Methods | O-ring seals (reusable), Bonded seals (high-pressure, single-use) |

| Material Choices | Steel, Stainless Steel, Brass |

| Pressure & Temperature Ratings | Must meet or exceed system requirements; safety margin recommended |

| Standards Referenced | ISO 6149, DIN 2353, BSPP |

| Compatibility Importance | Accurate matching prevents leaks, cross-threading, and failures |

Metric hydraulic fittings follow strict standards, such as ISO 6149 and DIN 2353, which define their design, material strength, and sealing methods. These fittings appear frequently in industrial automation, machine tools, and European automotive applications due to their reliability and precision.

What Are NPT Fittings?

NPT fittings, or National Pipe Tapered fittings, represent a widely used standard in North America. These fittings conform to ANSI B1.20.1 and feature tapered threads that create a seal through metal-to-metal contact as the male and female threads wedge together. This design allows NPT fittings to handle high static pressures and provides a secure connection. However, in dynamic hydraulic systems, experts often recommend alternative connections for improved leak resistance.

NPT thread specifications require careful attention to thread angle, taper ratio, and installation torque. The threads have a 60° angle and a 1:16 taper, which means the diameter decreases by 1/16 inch per inch of thread length. Proper installation involves wrapping the threads with PTFE tape, hand tightening, and then using a wrench for an additional 1.5 to 2 turns. Regular inspection and adherence to pressure test criteria ensure long-term performance.

Common Standards and Specifications

Hydraulic fittings must meet rigorous standards to ensure safety and compatibility. The most recognized standards for metric fittings include ISO 6149, DIN 2353, and BSPP. For NPT fittings, ANSI/ASME B1.20.1 and MILSPEC set the requirements. Certification markings often indicate thread size, material code, and pressure rating.

- ISO 80369-1 and ISO 80369-7 address small-bore connector design and dimensions.

- Thread Check Inc. manufactures gauges that comply with ASME/ANSI B5.10-1994 (R2008) and other international standards.

- Certification processes trace measurements to SI units via NIST, ensuring global consistency.

Tip: Always cross-reference thread measurements with standard charts and use certified gauges to avoid mismatches and ensure system reliability.

Typical Applications in Hydraulic Systems

Hydraulic systems power a wide range of machinery across industries. Engineers select Metric or NPT fittings based on system requirements, regional standards, and equipment origin. Each fitting type supports specific applications, ensuring optimal performance and safety.

Metric Fittings:

- Industrial Automation: Factories in Europe and Asia often use metric fittings in automated assembly lines, robotic arms, and CNC machines. These systems require precise connections and high reliability.

- Mobile Equipment: Tractors, excavators, and harvesters produced by European and Asian manufacturers rely on metric fittings. These fittings handle high-pressure fluid transfer in compact spaces.

- Automotive Manufacturing: Many automotive plants, especially those following ISO and DIN standards, use metric hydraulic fittings for assembly robots, presses, and test benches.

- Renewable Energy: Wind turbines and solar panel tracking systems in international projects often specify metric fittings for hydraulic actuation.

NPT Fittings:

- Construction Equipment: North American bulldozers, loaders, and cranes frequently use NPT fittings. These machines operate in rugged environments and require robust, field-serviceable connections.

- Oil and Gas: Drilling rigs, pipeline controls, and refinery systems in the United States and Canada depend on NPT fittings for their proven sealing under high pressure.

- Agricultural Machinery: Many American-made tractors and sprayers use NPT fittings in hydraulic steering and lifting systems.

- General Industrial Use: Factories in North America often specify NPT fittings for hydraulic presses, injection molding machines, and material handling equipment.

Note: Engineers must match fitting types to equipment specifications. Using the correct fitting ensures leak-free operation and simplifies maintenance.

The choice between Metric and NPT fittings often reflects the equipment’s country of origin and the prevailing industry standards. Global projects may require adapters or dual-standard systems to ensure compatibility across regions.

Key Differences Between Metric and NPT Fittings

Thread Type and Design

Metric and NPT fittings differ significantly in their thread geometry and measurement systems. Metric threads use millimeters for both diameter and pitch, following international standards. These threads can be parallel or tapered, depending on the application. The thread angle for metric fittings typically measures 60 degrees, which provides a balance between strength and ease of assembly. The diameter remains constant for parallel threads, while it decreases for tapered designs.

NPT threads, on the other hand, follow a unique tapered design with a precise taper angle of 1° 47′ (1.7899°). This taper ensures a tighter seal as the male and female threads compress together. NPT threads also use a 60-degree angle but are always measured in inches, with threads per inch (TPI) as the primary specification. The taper causes the diameter to decrease along the thread length, which enhances sealing by thread compression. NPT thread specifications require careful attention during selection and installation to ensure compatibility and leak prevention.

| Design Metric | Metric Threads | NPT Threads |

|---|---|---|

| Measurement Units | Millimeters (International standard) | Inches (North American standard) |

| Thread Type | Parallel or tapered depending on sealing needs | Always tapered with a taper angle of 1° 47′ (1.7899°) |

| Thread Angle | Typically 60 degrees (standard metric thread angle) | 60 degrees |

| Taper Angle | N/A (only if tapered, varies by standard) | Fixed taper angle of 1° 47′ (1.7899°) |

| Sealing Mechanism | Depends on thread type; parallel threads require sealants, tapered may seal by fit | Seals by thread compression due to taper; requires additional sealants like Teflon tape or pipe joint compound |

| Common Applications | Automotive, aerospace, industrial machinery | Plumbing, hydraulic, pneumatic, gas systems |

| Diameter Variation | Constant for parallel; decreases if tapered | Diameter decreases along thread length (tapered) |

| Threads Per Inch (TPI) | N/A (pitch measured in mm) | Specified in threads per inch (TPI) |

Metric threads generally offer finer pitch and more precise alignment, which suits applications requiring high accuracy and tensile strength. NPT threads, with their coarser pitch and self-sealing taper, excel in high-pressure environments and fluid or gas systems.

Sealing Methods

Sealing methods represent another critical difference between Metric and NPT fittings. Metric fittings often rely on advanced sealing technologies. O-rings, bonded seals, or metal-to-metal contact provide leak-free performance, especially in high-pressure hydraulic systems. Parallel metric threads typically require an additional sealing element, such as an O-ring, to prevent fluid escape. Tapered metric threads may achieve a seal through thread interference, but designers still recommend supplementary seals for demanding applications.

NPT fittings depend on the mechanical compression of tapered threads to create a seal. As the threads tighten, the taper forces the metal surfaces together, forming a pressure-resistant barrier. However, this method alone may not guarantee a leak-free connection, especially under vibration or thermal cycling. Installers commonly use Teflon tape or pipe joint compound to fill microscopic gaps and enhance sealing reliability. This approach works well in plumbing, gas, and hydraulic systems where a robust seal is essential.

- NPT fittings have tapered threads and rely on sealing compounds for leak prevention.

- NPT fittings are easier to install compared to fittings requiring precise alignment.

- NPT fittings may require more frequent maintenance to re-tighten or re-seal connections.

Metric fittings, with their focus on precision and reusable seals, often reduce maintenance intervals and improve long-term reliability. NPT fittings, optimized for sealing and high-pressure environments, remain a popular choice in North American industries.

Regional Usage and Industry Adoption

Regional preferences for Metric and NPT fittings reflect historical standards, regulatory requirements, and industry practices. North America overwhelmingly favors NPT threads, driven by mature industries such as oil and gas, construction, and water management. The United States and Canada both emphasize safety and durability, with regulatory bodies supporting the continued use of NPT thread specifications in critical infrastructure.

Asia-Pacific countries, including China, India, and Southeast Asia, predominantly use metric threads. Rapid industrialization, urban development, and government support for manufacturing have accelerated the adoption of metric and BSP threads. These regions consume large volumes of hydraulic fittings for construction, water infrastructure, and energy projects.

Europe prefers BSP threads, especially in advanced technologies and green building initiatives. Energy efficiency regulations and sustainability goals encourage the use of BSP and metric fittings in industrial and commercial applications.

| Region | Dominant Thread Type(s) | Key Industry Drivers and Usage Patterns |

|---|---|---|

| North America | NPT | Mature industries (oil & gas, construction, water management); strong demand in U.S.; regulatory emphasis on safety and durability; Canada driven by mining and natural resources sectors. |

| Asia-Pacific | Metric (and BSP in parts) | Rapid industrialization and urban development in China, India, Southeast Asia; high consumption in construction, water infrastructure, energy projects; emerging manufacturing hub with government support. |

| Europe | BSP | Preference for BSP threads due to advanced technologies, green building standards, energy efficiency regulations promoting sustainable coupling solutions. |

The hydraulic hose and fittings market continues to grow, with a projected CAGR of 5.72% from 2024 to 2030. Automation, renewable energy, and regulatory focus on quality drive this expansion. Thread types, including BSP, Metric, and NPT, segment the market by end connections, reflecting regional preferences and industrial applications.

Note: Understanding regional standards and industry adoption rates helps procurement teams select the right fittings for global projects and ensures compliance with local regulations.

Compatibility and Interchangeability

Compatibility and interchangeability play a crucial role in global hydraulic system design and procurement. Engineers often face challenges when integrating Metric and NPT fittings within the same system. These challenges stem from differences in thread geometry, sealing methods, and regional standards.

Direct Compatibility Limitations

Metric and NPT fittings do not connect directly. The thread profiles, diameters, and sealing mechanisms differ. Attempting to force a connection between these two types can result in leaks, thread damage, or system failure. For example, a metric male fitting will not properly engage with an NPT female port. The threads will not align, and the seal will not form.

Adapter Solutions

Engineers use adapters to bridge the gap between Metric and NPT fittings. Adapters feature one end with a Metric thread and the other with an NPT thread. This design allows seamless integration of components sourced from different regions or manufacturers.

Tip: Always verify the pressure rating and material compatibility of adapters before installation. Adapters must meet or exceed the system’s operating requirements.

Common Adapter Types

- Straight Adapters: Connect Metric to NPT in a straight line.

- Elbow Adapters: Change direction while transitioning between thread types.

- Tee Adapters: Allow branching of hydraulic lines with mixed thread standards.

Interchangeability Table

| Fitting Type | Direct Interchangeability | Adapter Required | Typical Use Case Example |

|---|---|---|---|

| Metric ↔ Metric | Yes | No | European machinery, ISO/DIN systems |

| NPT ↔ NPT | Yes | No | North American equipment |

| Metric ↔ NPT | No | Yes | Global projects, imported machinery |

| BSP ↔ Metric/NPT | No | Yes | UK/EU to US/Asia integration |

Best Practices for Ensuring Compatibility

- Identify Thread Types: Use thread gauges and reference charts to confirm fitting standards.

- Check System Pressure: Select adapters and fittings rated for the highest system pressure.

- Review Material Selection: Ensure all components resist corrosion and chemical attack.

- Consult Technical Drawings: Reference detailed drawings to avoid mismatches.

- Source from Reputable Suppliers: Choose suppliers with proven expertise in global hydraulic standards.

Note: Mixing thread types without proper adapters can void equipment warranties and compromise safety.

Global Project Considerations

International projects often require a mix of Metric and NPT fittings. Procurement teams must plan for adapters and ensure all components meet local regulations. Standardizing on one thread type simplifies maintenance and reduces inventory complexity. However, when standardization is not possible, high-quality adapters provide a reliable solution.

Summary

Compatibility and interchangeability between Metric and NPT fittings demand careful planning. Adapters enable global integration, but only when selected and installed correctly. Engineers who understand these principles ensure safe, efficient, and reliable hydraulic systems across borders.

Side-by-Side Comparison Table

Thread Profile

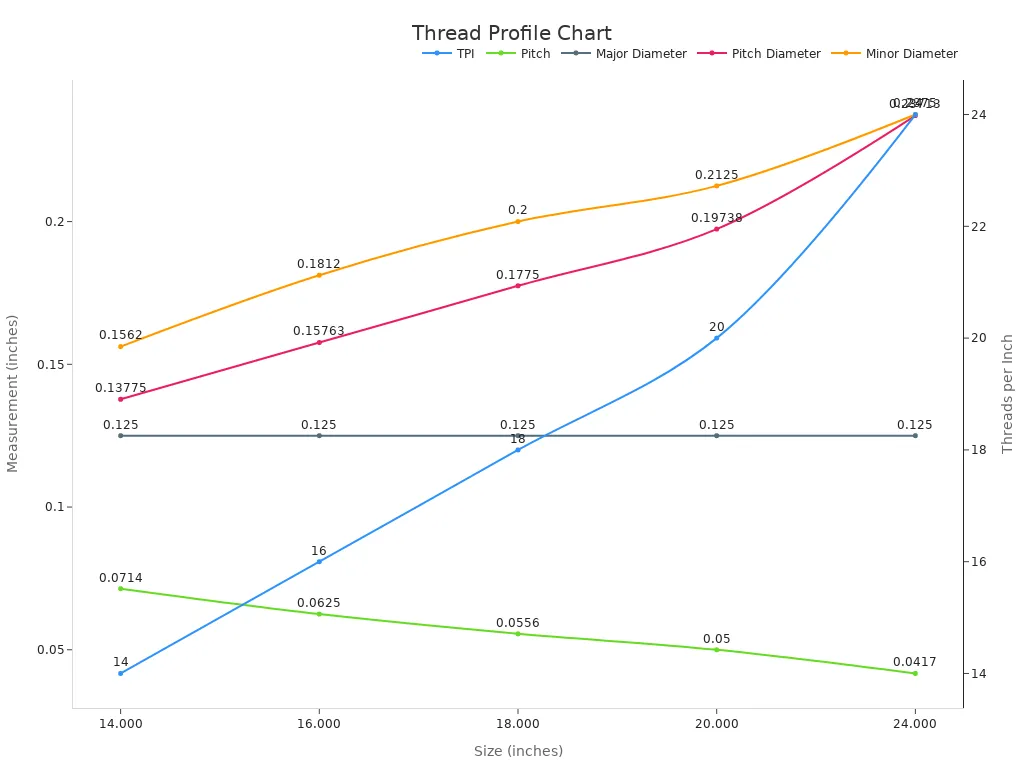

Thread profiles define the core differences between Metric and NPT fittings. Metric threads use millimeters for both diameter and pitch, such as M12x1.0, which means a 12 mm outer diameter and a 1.0 mm thread pitch. NPT threads, on the other hand, follow inch-based sizing and always feature a tapered profile. The npt thread specifications include a 60-degree thread angle and a 1:16 taper, which ensures a tight seal as the threads compress.

Manufacturers measure thread profiles using precise tools to ensure compatibility. Even small differences in pitch or diameter can prevent a proper seal. The table below highlights key measurements and tolerances for common thread standards:

| Thread Standard / Type | Key Measurements and Tolerances | Description |

|---|---|---|

| Metric Threads (e.g., M12x1.0) | Outer diameter in mm, pitch in mm | Metric threads specify true sizes; e.g., M12x1.0 means 12 mm outer diameter with 1.0 mm thread pitch. |

| NPT (ASME B1.20.1) | Threads per inch, taper, major diameter | Tapered threads, 60° angle, measured in inches; sealing by thread compression. |

| BSPT, BSPP | Threads per inch, major diameters | BSPT is tapered, BSPP is parallel; both use inch-based sizing. |

| SAE, JIC, DIN, JIS | Thread pitch, angle, diameter | Various standards with specific thread angles and numeric size tables. |

Accurate measurement and adherence to standards prevent leaks and ensure system reliability.

Sealing Mechanism

Sealing mechanisms differ significantly between Metric and NPT fittings. Metric fittings often use O-rings or bonded seals, which provide a reusable and reliable seal. These seals sit between the fitting and the port, preventing fluid from escaping even under high pressure. Parallel metric threads require these additional sealing elements, while some tapered metric threads can seal by thread interference.

NPT fittings rely on the compression of tapered threads to form a seal. As the male and female threads tighten, the taper forces the metal surfaces together. Installers often use Teflon tape or pipe joint compound to fill any gaps and enhance the seal. This method works well for static applications but may require periodic maintenance in dynamic systems.

- Metric: O-ring or bonded seal, reusable, high-pressure rated.

- NPT: Thread compression, requires sealant, may need re-tightening.

Regional Prevalence

Metric and NPT fittings dominate different regions due to historical standards and industry practices. Metric fittings appear most often in Europe and Asia, where ISO and DIN standards guide manufacturing. These regions favor metric threads for their precision and compatibility with international equipment.

NPT fittings remain the standard in North America. Industries such as oil and gas, construction, and agriculture rely on npt thread specifications for robust and field-serviceable connections. Adapters allow integration between systems, but direct interchangeability does not exist.

| Region | Preferred Thread Type | Typical Industries |

|---|---|---|

| North America | NPT | Oil & Gas, Construction, Agriculture |

| Europe, Asia | Metric, BSP | Manufacturing, Automation, Energy |

Understanding regional preferences helps procurement teams source the correct fittings for global projects.

Typical Applications

Hydraulic systems rely on a wide range of fitting types to meet the demands of different industries and operating environments. Engineers select fittings based on pressure requirements, available space, and the need for leak-free performance. The following table summarizes common fitting types, their typical applications, and the features that support their use:

| Fitting Type | Typical Applications and Scenarios | Key Features Supporting Use |

|---|---|---|

| Barb Fittings | Irrigation systems, fuel lines, air hoses (low-pressure uses) | Barbed end grips hose internally; easy installation; versatile |

| Bead Fittings | HVAC systems, industrial machinery, high-pressure hydraulics | Raised bead for secure clamping; withstands high mechanical stress |

| Banjo Fittings | Automotive fuel and brake lines, tight-space hydraulic systems | Compact design; enables fluid flow in confined areas |

| ORFS (Face Seal) | Offshore oil and gas, aerospace, heavy machinery, marine, vibration-prone areas | Flat face with O-ring seal; leak prevention; resists vibration |

| JIC Fittings | Automotive, aerospace, industrial hydraulics (primarily North America) | 37-degree flare; high reliability; SAE J514 standard |

Engineers often choose ORFS fittings for high-pressure and vibration-prone environments, while JIC fittings remain popular in North American automotive and industrial sectors. Banjo fittings excel in compact assemblies where space is limited.

Adapter Availability

Procurement teams frequently encounter the need to connect components with different thread standards, especially in global projects. NPT adapters are widely available in the market, with sizes ranging from 1/8″ to 3/4″ inner diameter. These adapters support a variety of tubing and pipe connections, making them a staple in North American hydraulic systems.

While many suppliers offer a broad selection of adapters for NPT and other thread types, listings do not always specify adapters designed to connect Metric fittings directly to NPT threads. However, the hydraulic fittings market includes a diverse range of adapters and connection types. Manufacturers often provide customized solutions to bridge Metric and NPT standards, responding to regional manufacturing needs and supply chain strategies. Leading suppliers emphasize flexibility in their product portfolios, ensuring that cross-standard adapters are available for specialized applications.

Procurement specialists should consult with experienced manufacturers to confirm the availability of Metric-to-NPT adapters and ensure compatibility with system requirements. Custom development remains an option for unique or large-scale projects.

npt thread specifications and Metric Standards

NPT Thread Dimensions and Taper

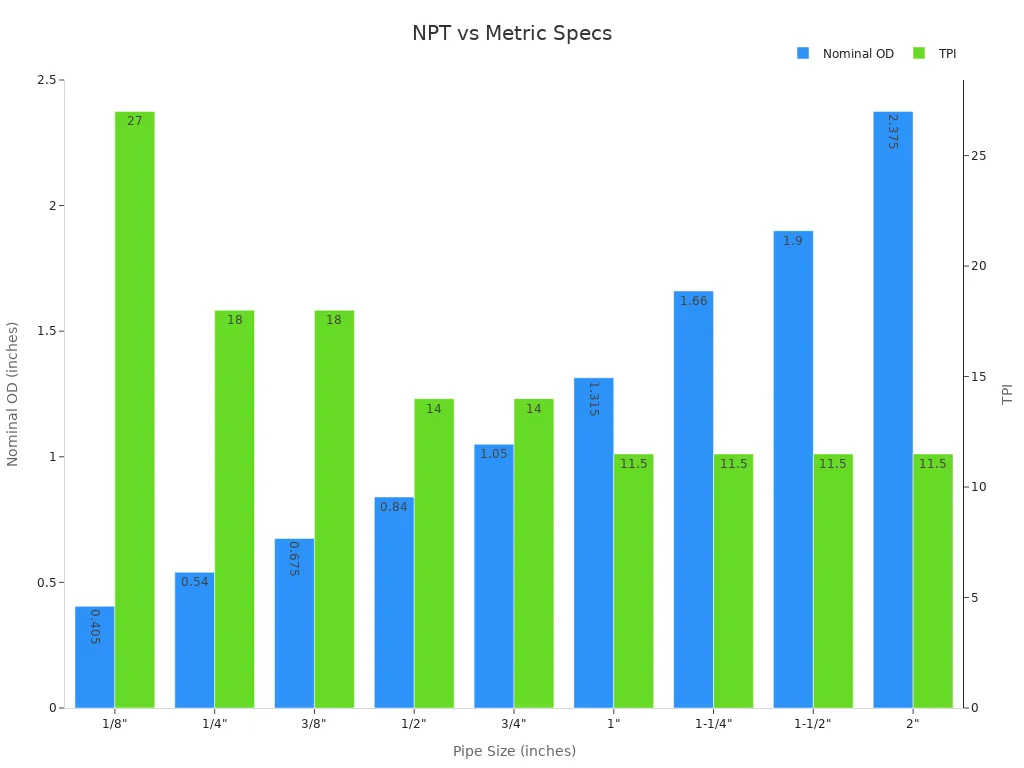

NPT thread specifications define the geometry and performance of pipe fittings in North American hydraulic systems. These threads feature a 60° angle and a consistent taper rate of 1 in 16 inches. The taper ensures a tight, pressure-resistant seal as the male and female threads compress. Engineers measure pitch in threads per inch (TPI), and pipe sizes are nominal, not matching the actual outside diameter. The table below summarizes standard NPT dimensions:

| Pipe Size (inches) | Threads Per Inch (TPI) | Nominal Outside Diameter (inches) | Tap Drill Size (inches) |

|---|---|---|---|

| 1/8″ | 27 | 0.405 | R (unspecified) |

| 1/4″ | 18 | 0.540 | 7/16 |

| 3/8″ | 18 | 0.675 | 37/64 |

| 1/2″ | 14 | 0.840 | 23/32 |

| 3/4″ | 14 | 1.050 | 59/64 |

| 1″ | 11.5 | 1.315 | 1-5/32 |

| 1-1/4″ | 11.5 | 1.660 | 1-1/2 |

| 1-1/2″ | 11.5 | 1.900 | 1-47/64 |

| 2″ | 11.5 | 2.375 | 2-7/32 |

NPT threads require sealant or PTFE tape for leak-free operation. The chart below visually compares nominal outside diameters and TPI values for common NPT sizes:

Metric Thread Types and International Standards

Metric threads follow ISO 724 standards and use a straight (non-tapered) profile. The designation starts with ‘M’, followed by the diameter in millimeters and the pitch (distance between threads), such as M12 x 1.5. Both NPT and metric threads share a 60° flank angle, but metric threads measure pitch in millimeters, not TPI. Metric threads appear in many global hydraulic systems due to their precision and compatibility with international equipment.

- Metric threads are straight, not tapered.

- The format is ‘M’ plus diameter and pitch (e.g., M18 x 1.5).

- Pitch is measured in millimeters.

- Metric threads use a 60° flank angle.

Identifying Threads in Practice

Engineers must identify thread types accurately to prevent leaks and ensure system compatibility. Several practical guidelines help in the field:

- NPT threads taper toward the end, while metric threads remain parallel.

- JIC fittings show a shiny 37° flare, and ORFS fittings have a flat face with an O-ring groove.

- Use caliper-style thread gauges and screw pitch gauges to measure diameter and pitch.

- Never force mismatched threads, such as NPT into BSPP.

- Always check the sealing method—taper, O-ring, or washer.

Correct identification of npt thread specifications and metric standards reduces installation errors and extends the life of hydraulic components.

Global Procurement Considerations

Assessing System Requirements

Procurement teams begin by evaluating the specific needs of each hydraulic system. They consider factors such as operating pressure, temperature range, fluid type, and the mechanical environment. These parameters determine the required material strength, corrosion resistance, and sealing method for each fitting. For example, systems exposed to harsh chemicals or extreme temperatures may require stainless steel or brass fittings, while standard industrial applications often use carbon steel.

Market data shows that leading industry players, including Eaton and Parker Hannifin, offer a wide range of hydraulic fittings tailored to diverse sectors like construction, agriculture, and aerospace. Procurement specialists analyze market segmentation by material type and end-user sector to select components that align with both technical requirements and budget constraints. They also monitor trends such as rising metal prices and the growing demand for green infrastructure, which influence both cost and material selection.

A structured approach to system assessment includes:

- Reviewing technical drawings and system schematics.

- Consulting with engineers to confirm pressure and flow requirements.

- Identifying environmental factors that may affect material choice.

- Evaluating the need for custom or OEM solutions based on unique project demands.

Tip: Early collaboration between engineering, procurement, and quality assurance teams streamlines the selection process and reduces the risk of costly design changes later.

Understanding Regional Standards and Regulations

Global projects must comply with a complex landscape of regional standards and regulations. Each region enforces its own rules regarding hydraulic fittings, driven by safety, environmental, and industry-specific requirements. North America typically mandates compliance with ANSI and SAE standards, while Europe relies on ISO and DIN specifications. Asia Pacific countries often adopt a mix of international and local standards, reflecting rapid industrial growth and diverse manufacturing practices.

Procurement teams stay informed about regulatory updates and certification requirements. They track strategic alliances and acquisitions, such as Danfoss acquiring Eaton’s hydraulic business, which can shift market dynamics and influence the availability of compliant products. Vendor landscapes and SWOT analyses help identify suppliers with proven track records in meeting regional standards.

A practical checklist for navigating regional regulations includes:

- Verifying that all fittings carry the necessary certifications for the target market.

- Consulting local authorities or industry bodies for up-to-date compliance information.

- Selecting suppliers with experience in cross-border projects and multi-standard manufacturing.

- Reviewing documentation for traceability and quality assurance.

Note: Failure to comply with regional standards can result in project delays, fines, or system failures. Proactive research and supplier engagement minimize these risks.

Ensuring Component Compatibility

Component compatibility stands at the core of successful global hydraulic system integration. Engineers and procurement teams must validate that all fittings, hoses, and adapters work together seamlessly, regardless of their origin. Compatibility testing ensures that components meet performance expectations and maintain system integrity under real-world conditions.

Modern test platforms, such as modular pre-engineered systems, enable rapid validation of hydraulic components across international standards. These systems provide reliable data on pressure ratings, sealing performance, and material compatibility. Standardized tests, including viscosity, oxidation stability, and wear resistance, confirm that fluids and elastomers perform as required. Elastomer compatibility tests, for example, ensure that seals and hoses retain their properties when exposed to hydraulic fluids over time and varying temperatures.

A step-by-step approach to ensuring compatibility includes:

- Identifying all thread types and sealing methods in the system.

- Conducting laboratory tests for fluid and material compatibility.

- Reviewing supplier data sheets and test reports for each component.

- Using adapters only when necessary and verifying their pressure ratings.

- Documenting all compatibility checks for future reference and maintenance planning.

| Compatibility Test | Purpose | Standard Reference |

|---|---|---|

| Viscosity Testing | Confirms fluid flow and lubrication | ASTM D445-97 |

| Oxidation Stability | Prevents sludge and varnish formation | ASTM D2272 |

| Wear Resistance | Ensures longevity of pumps and valves | ASTM D2266 |

| Elastomer Compatibility | Maintains seal integrity over time | Custom/Industry Tests |

Callout: Comprehensive compatibility validation reduces the risk of leaks, premature wear, and costly downtime in international hydraulic projects.

Sourcing and Availability of Fittings and Adapters

Global demand for hydraulic fittings and adapters continues to rise. Industrial growth and infrastructure projects drive this trend. The Hydraulic Adapters Market report projects the market size to grow from USD 2.5 billion in 2023 to USD 3.4 billion by 2032. Major players such as Eaton Corporation and Parker Hannifin Corporation lead the industry, but many specialized manufacturers also contribute to the supply chain. Urbanization and construction activity in emerging markets increase the need for reliable sourcing channels.

Procurement teams must evaluate both the breadth and depth of available products. Sourcing reports use a combination of primary and secondary research to identify key suppliers and integration techniques. These reports gather data from industry leaders, government sources, and company news. Cross-validation of information ensures accuracy and reliability. Verified Market Research employs data triangulation and econometric models to analyze trends. Data comes from fabricators, wholesalers, competitor reports, and end-user surveys. This multi-layered approach provides a clear picture of product availability and market segmentation.

Availability of fittings and adapters depends on several factors:

- Regional Manufacturing Hubs: Asia-Pacific, Europe, and North America each host major production centers. Local regulations and standards influence product types and inventory.

- Product Range: Suppliers offer a wide selection, including straight, elbow, tee, cross, and custom adapters. Material options include steel, stainless steel, and brass.

- Lead Times: Standard parts often ship quickly, while custom or specialty items may require longer production cycles.

- Distribution Networks: Global logistics partners and regional warehouses help maintain steady supply and reduce delivery times.

Procurement specialists should monitor market trends and maintain relationships with multiple suppliers. This strategy helps secure critical components and manage risks related to supply chain disruptions.

Working with Suppliers and Custom Development

Successful hydraulic projects depend on strong supplier partnerships. Leading companies like Huacheng Hydraulic invest in advanced manufacturing facilities and scientific management systems. Their operations include intermediate frequency galvanothermy forging, robotic production lines, cold header machines, and hundreds of CNC machines. These resources enable rapid response to customer needs and support both standard and custom product development.

When working with suppliers, procurement teams follow a structured process:

- Technical Review: Engineers review sample threads or drawing specifications, confirming all dimensions and tolerances.

- Requirement Communication: Teams discuss product demands, raw material selection, and any special concerns.

- Drawing Confirmation: Suppliers provide detailed drawings for customer approval.

- Quotation and Program Launch: After agreement, suppliers prepare quotations and initiate the custom program.

Custom development involves several key steps:

- Running sample production and adjusting parameters based on feedback.

- Sending samples to customers for verification before full-scale production.

- Preparing production flow charts, work instructions, and inspection guidelines to ensure quality control.

- Starting mass production only after all standards are met.

Companies with 3D modeling capabilities and professional engineering teams can deliver tailored solutions for unique hydraulic systems. OEM acceptance and the ability to produce according to customer samples or drawings further enhance flexibility.

Procurement teams benefit from choosing suppliers with robust technical support and transparent communication. This approach ensures that fittings and adapters meet all technical, regulatory, and operational requirements. Reliable suppliers help reduce lead times, minimize errors, and support long-term system performance.

Installation and Maintenance Best Practices

Installation Guidelines for Metric Fittings

Proper installation of metric fittings ensures leak-free performance and system longevity. Technicians should always clean threads and sealing surfaces before assembly. Lubrication of O-rings or bonded seals prevents damage during installation. Alignment of fittings remains critical; misalignment can cause premature wear or leaks. Torque wrenches help achieve the manufacturer’s recommended tightness, avoiding over-tightening that may deform seals.

Tip: Always verify thread type and size with a gauge before installation to prevent cross-threading.

Key steps for metric fitting installation:

- Inspect all components for damage or contamination.

- Apply compatible lubricant to O-rings and sealing surfaces.

- Hand-tighten fittings, then use a torque wrench to reach specified values.

- Check alignment and support hoses to reduce stress on connections.

Installation Guidelines for NPT Fittings

NPT fittings require a different approach due to their tapered thread design. Technicians should wrap male threads with PTFE tape or apply pipe joint compound to enhance sealing. Hand-tighten the fitting, then use a wrench for an additional 1.5 to 2 turns. Over-tightening can crack components or distort threads.

Note: Never mix NPT with metric threads without a proper adapter.

Best practices for NPT installation:

- Clean threads thoroughly before assembly.

- Apply sealant evenly, covering all threads except the first one or two.

- Tighten to the recommended torque, checking for proper engagement.

- Inspect for visible gaps or misalignment after installation.

Maintenance and Inspection Tips

Routine maintenance and inspection keep hydraulic systems reliable and safe. Standard Operating Procedures (SOPs) guide technicians through each step, reducing errors and supporting compliance. Ongoing training ensures maintenance teams stay updated on best practices and safety protocols.

- Maintenance inspections identify issues before costly repairs arise.

- Scheduled, documented inspections using maintenance management software improve traceability.

- Condition-monitoring tools, such as infrared thermometers, help detect problems early.

- Monitoring KPIs like Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) provides measurable reliability.

- Preventive maintenance schedules optimize resource allocation and minimize downtime.

Regular documentation, communication, and audits foster continuous improvement and transparency in maintenance procedures.

Common Issues and Troubleshooting

Hydraulic systems using Metric or NPT fittings can encounter several recurring issues. Technicians and engineers often face challenges during installation, operation, or maintenance. Recognizing these problems early helps maintain system reliability and safety.

1. Leaks at Connection Points

- Leaks often result from improper sealing, damaged O-rings, or insufficient thread engagement.

- NPT fittings may leak if installers do not apply enough PTFE tape or if over-tightening distorts the threads.

- Metric fittings can leak when O-rings are missing, cut, or not seated correctly.

Tip: Always inspect seals and threads before assembly. Replace damaged components immediately.

2. Cross-Threading

- Cross-threading occurs when installers force mismatched threads together.

- This issue damages both the fitting and the port, leading to leaks or system failure.

- Metric and NPT threads are not interchangeable. Attempting to connect them directly causes cross-threading.

3. Incorrect Torque Application

- Over-tightening can deform threads or crush sealing elements.

- Under-tightening may result in loose connections and leaks.

- Use a calibrated torque wrench and follow manufacturer specifications.

4. Compatibility Issues

- Mixing Metric and NPT fittings without proper adapters leads to poor sealing and mechanical failure.

- Adapters must match pressure ratings and material compatibility.

Troubleshooting Table

| Issue | Likely Cause | Recommended Action |

|---|---|---|

| Persistent Leaks | Damaged seal or thread | Replace seal, check thread |

| Cross-Threading | Mismatched threads | Use correct fitting and adapter |

| Loose Connections | Insufficient torque | Retighten to specification |

| Corrosion | Incompatible materials | Select proper material |

Note: Regular inspection and adherence to installation guidelines prevent most common issues. Training and clear documentation support effective troubleshooting.

Choosing the Right Fitting for Your Application

Decision-Making Checklist

Selecting the correct hydraulic fitting requires a systematic approach. Engineers and procurement teams benefit from a clear checklist that guides decision-making. The following steps help ensure the right choice for any application:

- Identify System Standards

Determine if the system follows Metric, NPT, BSP, or another standard. Reference technical drawings and equipment documentation.

- Confirm Pressure and Temperature Ratings

Check the maximum operating pressure and temperature. Select fittings that meet or exceed these requirements.

- Assess Fluid Compatibility

Review the type of hydraulic fluid in use. Choose materials that resist corrosion and chemical attack.

- Verify Thread Type and Size

Use thread gauges and calipers to measure threads accurately. Match fittings to system ports.

- Evaluate Sealing Method

Decide if the application needs O-rings, bonded seals, or thread sealants. Consider the environment and maintenance schedule.

- Check Regional Compliance

Ensure all components meet local and international standards. Review certifications and supplier documentation.

- Plan for Maintenance and Replacement

Select fittings that allow easy inspection and replacement. Consider the availability of adapters for future upgrades.

Tip: Document each step in the selection process. This practice supports traceability and simplifies future maintenance.

Case Examples in Global Hydraulic Projects

Real-world projects highlight the importance of proper fitting selection. The following examples illustrate best practices:

- European Automotive Plant

A manufacturer in Germany upgraded its assembly line. The team selected metric fittings according to ISO 6149. This choice ensured compatibility with existing equipment and simplified sourcing from local suppliers.

- North American Oilfield Operation

An oil company in Texas expanded its hydraulic fracturing fleet. Engineers specified NPT fittings for all new equipment. The decision matched regional standards and allowed field technicians to use familiar installation tools.

- Cross-Border Renewable Energy Project

A wind farm in Southeast Asia sourced turbines from Europe and control systems from the United States. The project team used adapters to connect metric and NPT fittings. This solution maintained system integrity and met both European and American standards.

These examples show that careful planning and adherence to standards lead to reliable, efficient hydraulic systems worldwide.

Selecting the right hydraulic fitting type shapes system performance, reliability, and cost-efficiency. Engineers who match pressure ratings to system needs and verify material compatibility prevent leaks and failures. Environmental factors like temperature, corrosion, and vibration resistance also influence fitting lifespan.

- Correct fitting choice reduces downtime and maintenance.

- ORFS and permanent fittings improve safety and durability in demanding environments.

- Reusable fittings offer flexibility for maintenance tasks.

Proactive procurement planning and consultation with experienced suppliers ensure global hydraulic systems remain efficient and compliant.

FAQ

What is the main difference between Metric and NPT fittings?

Metric fittings use millimeter-based threads and often rely on O-ring seals. NPT fittings use inch-based tapered threads that seal by thread compression. Each type follows different international standards and serves specific regional markets.

Can Metric and NPT fittings connect directly?

No, Metric and NPT fittings cannot connect directly. Their thread profiles and sealing methods differ. Engineers must use adapters designed for cross-standard connections to ensure a safe and leak-free system.

How do you identify a fitting’s thread type?

Technicians use thread gauges and calipers to measure diameter and pitch. Metric threads show millimeter measurements. NPT threads use inch sizing and a visible taper. Always check technical documentation for confirmation.

When should a project use adapters?

Projects use adapters when integrating equipment from different regions or when systems require both Metric and NPT fittings. Adapters bridge the gap between incompatible thread types and maintain system integrity.

What maintenance steps help prevent leaks in hydraulic fittings?

Technicians should inspect seals, clean threads, and use proper torque during installation. Regular maintenance includes checking for wear, corrosion, and correct alignment. Early detection and replacement of damaged parts prevent leaks and system failures.

Post time: Jun-27-2025