Huacheng Hydraulic engineers the ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 fittings for maximum reliability. These fittings use a precision O-ring face seal to create a strong barrier. This design stops hydraulic fluid loss and keeps systems running smoothly. Operators trust this solution for leak prevention.

Key Takeaways

- ORFS Male O-Ring Seal fittings create a strong, leak-proof barrier by compressing an O-ring between flat surfaces, stopping hydraulic fluid loss even under high pressure and vibration.

- These fittings offer high durability, resist damage from over-tightening, and can be reused multiple times with new O-rings, saving costs and extending system life.

- Regular maintenance, including inspecting and replacing O-rings and following proper installation steps, ensures reliable, leak-free hydraulic system performance.

How ORFS Male O-Ring Seal ISO 8434-3–SAE J1453 Prevents Leaks

O-Ring Face Seal Mechanism

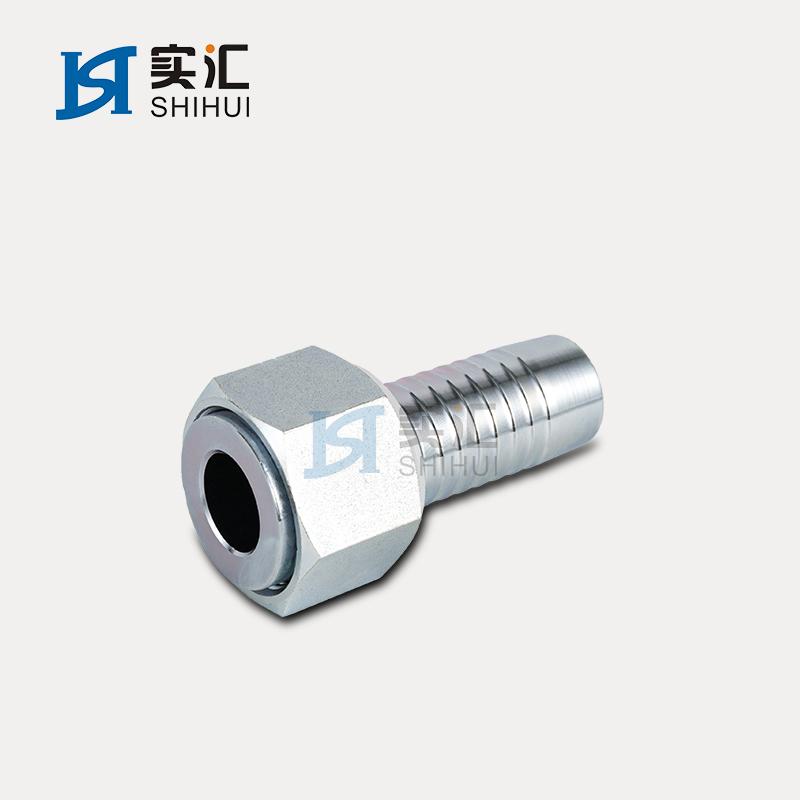

The ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 uses a unique sealing method. The O-ring sits in a groove on the face of the male fitting. When the fitting connects to the female side, the O-ring compresses against a flat surface. This action forms a tight, leak-proof barrier. The O-ring, made from elastomeric material, fills any small gaps or imperfections on the metal faces. This design stops fluid from escaping, even when the system faces high pressure or vibration.

Tip: Always choose an O-ring material that matches the hydraulic fluid and temperature range. This ensures the seal stays strong and reliable.

Compared to older fitting types, such as 37° flare or 24° flareless, the ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 offers better leak resistance. The O-ring face seal eliminates spiral leak paths that can occur with tapered threads. Industry standards like SAE J1453 and ISO 8434-3 confirm the reliability of this design through strict testing and performance requirements.

Compression Between Flat Faces

A key feature of this fitting is the compression between two flat faces. The male and female fittings must align perfectly. When tightened, the O-ring compresses evenly between the flat surfaces. This compression creates a nearly impermeable seal.

To ensure a leak-free connection, technicians follow these steps:

- Clean and inspect the flat faces and O-ring for damage or dirt.

- Place the O-ring in its groove, making sure it is not twisted.

- Insert the male fitting into the female side carefully.

- Hand-thread the connection, then tighten with a wrench to the correct torque.

- Check the alignment and O-ring compression.

- Test the connection under pressure to confirm no leaks.

Proper compression is vital. Even torque and clean surfaces help the O-ring fill any small gaps, keeping the hydraulic system sealed.

Performance Under High Pressure and Vibration

Hydraulic systems often operate under high pressure and face constant vibration. The ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 stands out in these tough conditions. The O-ring face seal can handle pressures up to 6000 PSI or more. The elastomeric O-ring absorbs movement and vibration, preventing the seal from loosening or leaking.

- ORFS fittings maintain their seal even when pressure or temperature changes.

- The O-ring resists vibration-induced loosening, which is common in metal-to-metal seals.

- The design allows for easy replacement of O-rings, making maintenance simple and cost-effective.

Many industries choose this fitting for critical systems, such as automotive brakes and heavy machinery, because it keeps hydraulic fluid contained and systems running safely.

Advantages of ORFS Male O-Ring Seal ISO 8434-3–SAE J1453 Fittings

High Pressure Capability and Durability

ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 fittings deliver outstanding performance in high-pressure environments. Field-proven case studies show that O-ring face seal fittings work reliably in helium compressor systems at 3,000 psi and in CO₂ refrigeration systems at elevated pressures. Stainless steel versions offer superior strength and corrosion resistance, making them ideal for demanding industries like aerospace and maritime. These fittings maintain leak-free connections even during extreme weather or heavy use. Advanced materials and precise engineering help them withstand harsh conditions and reduce maintenance needs.

Resistance to Over-Tightening and Reusability

Technicians often face challenges with over-tightening traditional fittings, which can damage threads or seals. ORFS fittings solve this problem. The flat face and O-ring design prevent damage from excessive torque. Users can assemble and disassemble these fittings multiple times without losing sealing performance. This feature supports cost savings and extends the life of hydraulic components.

Compatibility with Various Tubing and Materials

SAE J1453 certification ensures that these fittings work with a wide range of tubing and materials. The male connector uses a straight thread and an O-ring, while the female side has a flat face. This design allows for secure connections with different hose types and system components. Compatibility charts and installation guidelines help users select the right O-ring material for their hydraulic fluid, whether petroleum-based or synthetic. Proper torque values and post-installation leak checks further support reliable operation.

Tip: Always match thread types and O-ring materials to the system’s fluid and pressure requirements for best results.

Maintenance Tips for Leak-Free Operation

Regular maintenance keeps hydraulic systems running smoothly. Technicians should inspect O-rings and hoses, replacing them if worn or damaged. Before starting work, always depressurize the system and use lockout/tagout procedures for safety. Never reuse old O-rings after disassembly. Document each maintenance step and use real-time monitoring tools to catch early signs of leaks. Predictive maintenance, such as using IoT sensors, helps prevent failures and extends equipment life.

ORFS MALE O-RING SEAL ISO 8434-3–SAE J1453 fittings provide unmatched leak prevention in hydraulic systems. Manufacturers test these fittings to withstand extreme pressure spikes and repetitive cycles. Their advanced O-ring design ensures joint integrity, high pressure capability, and unlimited reusability. Huacheng Hydraulic delivers long-term reliability and fluid conservation.

FAQ

What makes ORFS Male O-Ring Seal ISO 8434-3–SAE J1453 fittings leak-resistant?

The O-ring face seal compresses between flat surfaces. This design blocks fluid paths and prevents leaks, even under high pressure or vibration.

Can technicians reuse ORFS Male O-Ring Seal fittings after disassembly?

Technicians can reuse the fittings. Always install a new O-ring for each assembly to maintain a reliable seal and prevent leaks.

Which industries use ORFS Male O-Ring Seal ISO 8434-3–SAE J1453 fittings?

- Construction equipment

- Agricultural machinery

- Marine systems

- Industrial hydraulics

These fittings support any application that demands secure, leak-free hydraulic connections.

Post time: Jun-27-2025