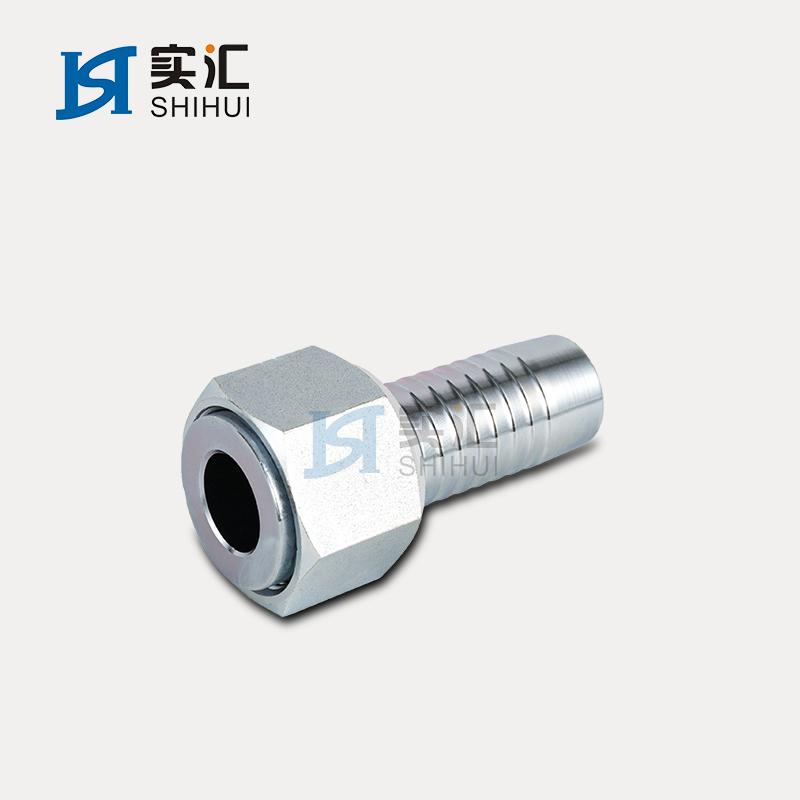

Leaks in an NPT Hose Fitting often result from improper installation, damaged threads, worn seals, or incorrect tightening. Industry reports highlight several key issues:

- Improper torque, cross-threading, and missing seals cause leaks.

- Most leaks appear at fitting connections due to installation errors.

- Experts stress proper installation to prevent leakage.

Key Takeaways

- Most NPT hose fitting leaks happen because of improper installation, such as wrong tightening or damaged threads. Proper training and careful work prevent these leaks.

- Regular inspection and maintenance of threads and seals help catch wear or damage early, keeping fittings secure and leak-free.

- Fixing leaks requires safe disassembly, cleaning, correct sealant use, proper tightening, and thorough testing to ensure a strong, lasting connection.

Common Causes of NPT Hose Fitting Leaks

Improper Installation

Improper installation stands as the leading cause of NPT Hose Fitting leaks. Many industry experts agree that user error accounts for most hydraulic leaks. The following points highlight why installation mistakes frequently result in leakage:

- User error, including improper installation, causes 60-90% of hydraulic leaks.

- Incorrect fitting use, improper tightening torque, and misalignment often lead to leaks.

- Thread deformation and mis-sizing of NPT fittings contribute to sealing failures.

- Poor workmanship, lack of training, and inadequate maintenance practices make leakage problems worse.

- One expert notes that 70% of leaks stem from improper hose or tubing installation or incorrect fitting connections.

- Most leaks result from user error, not component failure, making proper education and training essential.

Proper installation techniques and regular training help reduce the risk of leaks in NPT Hose Fitting connections.

Thread Damage or Wear

Thread damage or wear can compromise the seal in an NPT Hose Fitting. Visual inspection often reveals wear indicators such as flattening, nicks, or corrosion. Technicians may run their fingers over the threads to detect rough or uneven surfaces. Thread gauges check for proper engagement and fit, while calipers and micrometers measure roundness and thread dimensions at multiple points. Digital thread profiling tools provide accurate dimension capture, even when wear is present. Consistent re-measurement with calibrated instruments ensures accuracy, and cross-checking with multiple gauges or third-party verification confirms thread integrity.

Thread galling, a form of adhesive metal wear, occurs when friction and pressure cause metal to tear and cold weld between mating threads. This process leads to scoring and thread damage, distorts the threads, and creates debris that can contaminate the connection. Galling is especially common in stainless steel tapered threads like NPT. Damage from galling or repeated assembly causes permanent thread deformation, which compromises the seal and leads to leaks. Preventive measures include using specialty sealants or anti-seize lubricants and avoiding overtightening.

Over-Tightening or Under-Tightening

Correct tightening is crucial for a leak-free NPT Hose Fitting. Over-tightening can deform threads, crush seals, and even crack the fitting body. This damage weakens the connection and increases the risk of leaks. Under-tightening, on the other hand, fails to compress the threads and seals enough to create a proper seal. Both extremes prevent the fitting from achieving the tapered thread engagement necessary for a leak-resistant connection. Technicians should always follow manufacturer torque specifications and use calibrated tools to ensure proper tightening.

Worn or Missing Seals

Seals play a vital role in preventing leaks in NPT Hose Fitting assemblies. Over time, seals can wear out, harden, or become brittle due to exposure to hydraulic fluids, temperature changes, or mechanical stress. Missing seals leave gaps that allow fluid to escape, while worn seals lose their ability to maintain a tight seal under pressure. Regular inspection and timely replacement of seals help maintain the integrity of the fitting and prevent leaks.

How to Fix NPT Hose Fitting Leaks Step by Step

Identify and Confirm the Leak Source

Technicians begin by ensuring safety. They depressurize the hydraulic system and wear personal protective equipment. A clean, organized workspace reduces hazards and improves efficiency.

To pinpoint the leak, they use visual inspection and pressure testing. Pressure gauges, hydrostatic tests, or vacuum tests help locate the exact source. Sometimes, a small leak may only appear under pressure, so monitoring during operation is essential.

Tip: Never touch leaking hydraulic fluid directly. High-pressure fluid can cause serious injury.

Disassemble the Fitting Safely

After confirming the leak, technicians prepare for disassembly. They release all system pressure to prevent fluid ejection. Proper body posture and tool use help avoid accidental injuries.

The process includes:

- Removing any additional fasteners or clamps.

- Using professional removal tools to loosen the NPT Hose Fitting, not relying on manual force.

- Carefully separating the fitting from the hose, avoiding damage to threads or components.

For push-on fittings, a 1-inch cut along the barbed end allows safe removal. The technician grips the hose and pulls sharply downward to release the fitting.

Note: Always check the manufacturer’s guidelines for specific disassembly instructions.

Inspect Threads and Seals

Inspection is critical for identifying the root cause of leaks. Technicians examine threads for signs of cross-threading, wear, corrosion, or galling. They use thread gauges and calipers to measure pitch and diameter, ensuring proper fit.

Seals receive close attention. Worn, brittle, or missing seals often cause leaks. If the fitting has carried hazardous fluids, thorough inspection becomes even more important.

Regular scheduled inspections help detect early signs of wear or damage.

Blocked or damaged threads, improper sealant application, or overtightening often become visible during this step.

Clean and Prepare the Fitting

All components must be free of debris, oil, and old sealant before reassembly. Technicians use lint-free cloths and appropriate cleaning agents.

They remove any residual hydraulic oil and apply lubricating oil to new gaskets if needed. Clean threads ensure proper engagement and prevent contamination.

A clean fitting surface is essential for a reliable seal and long-term leak prevention.

Apply Thread Sealant or Teflon Tape

Proper sealing prevents leaks and extends the life of the NPT Hose Fitting. Technicians select the right sealant for the application.

- Teflon tape works well for standard plumbing and smaller pipes. It acts as a lubricant and helps fill spiral leak paths.

- Anaerobic thread sealants cure to form strong, vibration-resistant seals. These perform best in high-pressure or high-vibration environments.

- Pipe dope provides a moderate seal but may shrink or crack over time.

Operator skill and correct application matter more than the sealant type. Studies show that proper technique and torque prevent leaks, regardless of the sealant used.

For best results, technicians avoid over-wrapping Teflon tape and ensure even coverage. They never reuse old sealant.

Reassemble and Tighten Correctly

Reassembly requires careful alignment of the fitting and hose. Technicians use a torque wrench to tighten the NPT Hose Fitting to manufacturer specifications.

Over-tightening can deform threads or crack the fitting. Under-tightening may leave gaps for leaks.

They replace O-rings or seals as needed and ensure all components fit securely.

Proper torque and alignment are key to a leak-free connection.

Test for Leaks

After reassembly, technicians restore system pressure gradually. They monitor the connection for leaks using pressure gauges and visual inspection.

Functional tests confirm that the repair holds under normal operating conditions.

If a leak persists, they repeat the inspection and repair process, replacing any compromised parts.

Regular testing and maintenance keep hydraulic systems safe and reliable.

Troubleshooting Persistent NPT Hose Fitting Leaks

Check Thread Compatibility

Thread compatibility issues often cause persistent leaks. Technicians should compare thread pitch, angle, and size to ensure a proper match. NPT threads have a 60° angle and specific pitches, while BSP threads use a 55° angle and different pitches. Mismatched threads can lead to poor engagement and spiral leakage. The table below highlights key diagnostic criteria:

| Diagnostic Criteria | NPT Specification | BSP Specification | Compatibility Impact |

|---|---|---|---|

| Thread Pitch (TPI) | 27, 18, 14, 11.5 | 28, 19, 14 | Mismatched pitch causes misalignment and leakage |

| Thread Angle | 60° | 55° | Different angles cause poor engagement and spiral leakage |

| Thread Size Examples | 1/8″, 1/4″, 1/2″, 1″ | Similar sizes, different pitch and angle | Size and pitch differences critical for sealing |

| Thread Engagement | Varies by pitch | Varies by pitch | Incorrect engagement leads to leaks |

Technicians should always use thread sealants like Teflon tape with NPT threads and avoid mixing thread types without proper adapters.

Look for Cracks or Deeper Damage

Persistent leaks may signal cracks or hidden damage. Technicians use several inspection methods:

- Visual inspection for cracks, deformation, or discoloration.

- Calipers and micrometers to measure crack length and width.

- Ultrasonic thickness gauges to detect wall thinning.

- Non-destructive testing, such as dye penetrant or magnetic particle testing, to reveal internal flaws.

- Leak detection fluids and ultrasonic detectors to pinpoint small or hidden leaks.

Tip: Fluorescent dye testing helps identify leaks that are hard to see with the naked eye.

Replace the Fitting if Needed

If inspection reveals severe thread damage, cracks, or deformation, replacement becomes necessary. Technicians should select a new NPT Hose Fitting that matches the system’s specifications. They must follow manufacturer torque guidelines and use proper tools during installation. Adhering to these steps ensures a secure, leak-free connection and restores system reliability.

Quick action prevents leaks from causing costly damage or safety hazards.

- Licensed technicians recommend regular inspections and cleaning to maintain system reliability.

- Proper installation, including careful alignment and correct torque, creates secure, long-lasting connections.

- Routine maintenance reduces repairs and extends the life of hydraulic fittings.

FAQ

What is the main reason NPT hose fittings leak?

Improper installation remains the leading cause. Technicians often find that incorrect torque or misaligned threads create gaps, allowing fluid to escape.

How often should technicians inspect NPT hose fittings?

Technicians should inspect fittings during every scheduled maintenance cycle. Early detection of wear or damage prevents unexpected leaks and system failures.

Can technicians reuse thread sealant or Teflon tape?

Technicians should always use new thread sealant or Teflon tape. Reusing old material reduces sealing effectiveness and increases the risk of leaks.

Post time: Jun-27-2025